- Shipping Company Estimated Delivery Time Shipping Cost

- This item cannot be shipped at your location

Highlights

95% Pre-Assembly

DIY all-in-one structure, the Sidewinder X2 comes 95% pre-assembled, which makes installation easy as can be. 3 minutes to complete assembly.

Fast Printing Speed

The print speed of Artillery Sidewinder X2 can reach up to 150mm/s, and the 0.4mm direct drive extruder makes high-quality print, especially for flexible filament.

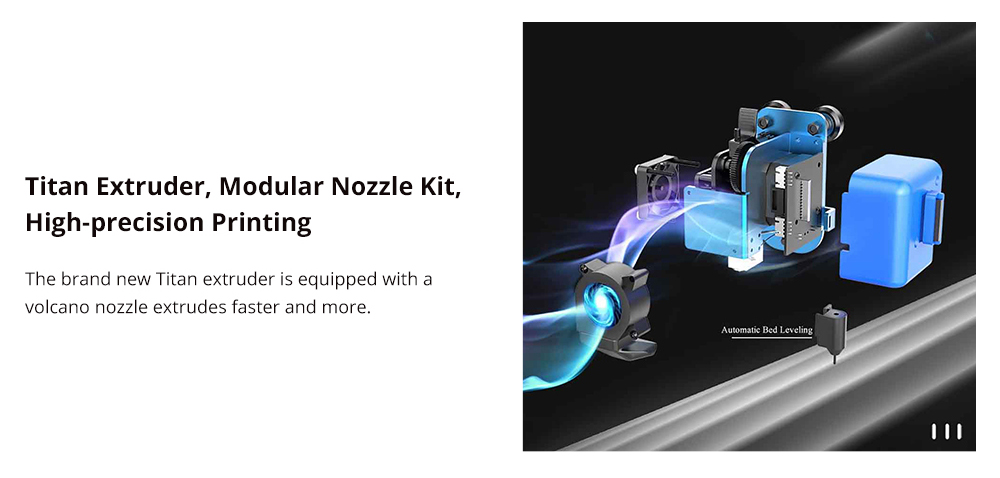

Automatic Bed Leveling

With matrix automatic bed leveling, Intellisense, and precise testing, the device supports dynamic leveling compensation and frees you from complex manual leveling, which proves to be efficient and intelligent.

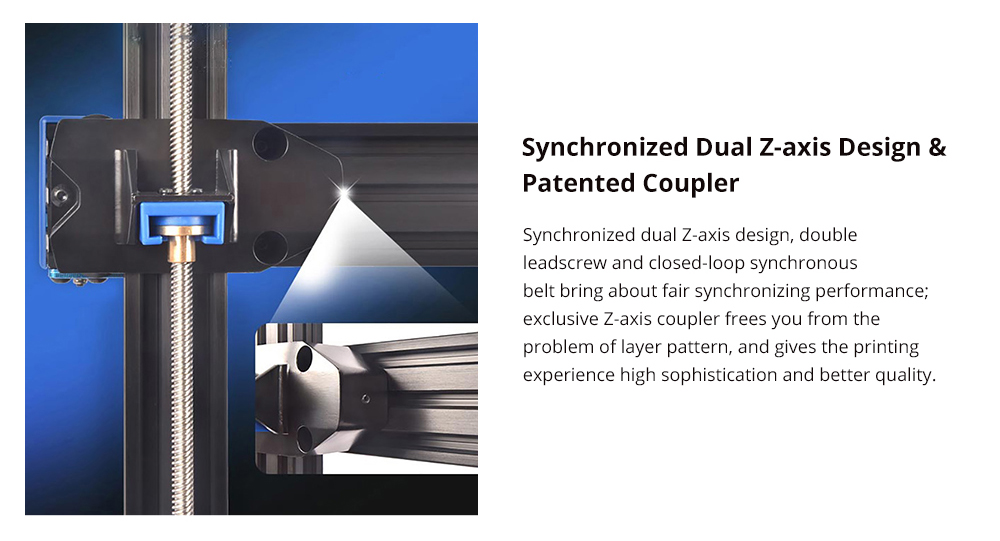

Synchronized Dual Z System

There are 3 inductive sensor end stop separately set on the XYZ axis while those non-touch, high-precision limit switches can automatically calibrate and maintain good stability under high-speed printing. Most importantly, the synchronized dual Z system greatly increases its printing stability.

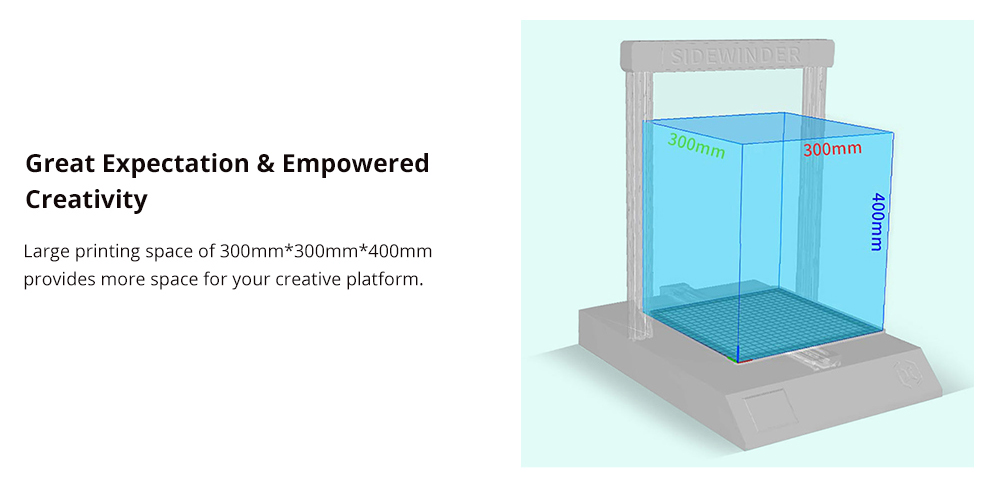

Large Build Volume & Color Touchscreen Control

Sidewinder X2 3D printer features a 300 x 300 x 400mm build volume and color touchscreen control. It is simple and easy to understand the operating interface, bringing you more possibilities for creating your 3D printings.

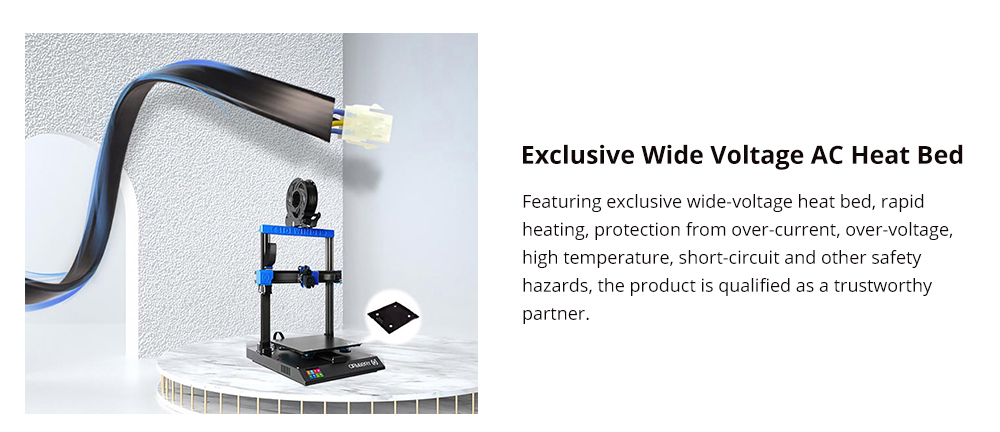

Tempered Glass Platform & AC Heat Bed

The printer has a direct drive extruder and a fast-heating AC heat bed with built-in thermal runaway protection, even if the board or the SSR malfunctioned, the bed won’t heat up endlessly until bad things happen. AC heat bed can be heated to 110 Celsius in 2 minutes. The tempered glass platform makes print more smoothly and adheres well.

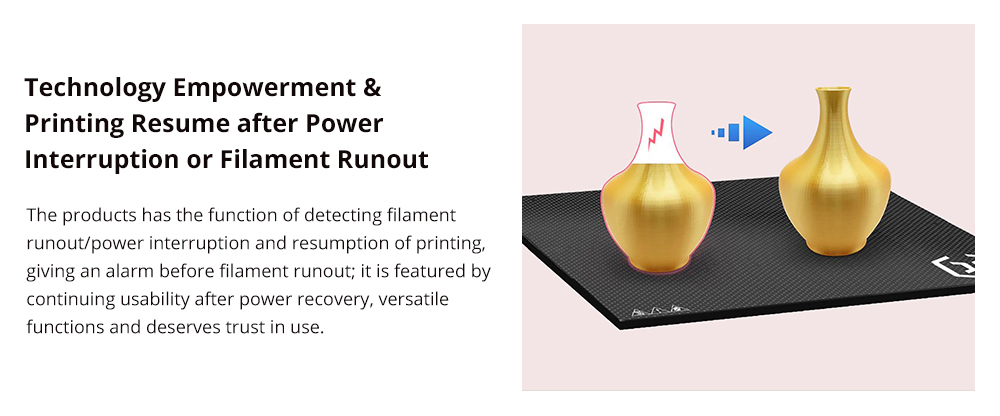

Resume Printing Function

The product has the function of detecting filament runout and power interruption and resumption of printing, giving an alarm before filament runout; it is featured by continuing usability after power recovery, versatile functions, and deserves trust in use.

Exclusive Ultra-quiet Stepper Driver

The ultra-quiet system, assisted by the exclusive ultra-quiet stepper driver, undergoes high-load safety testing during which the machine operates at low decibels throughout the entire process, thus realizing quiet printing.

Specification

| General | Brand: Artillery Type: 3D printer Model: Sidewinder X2 Color: Black |

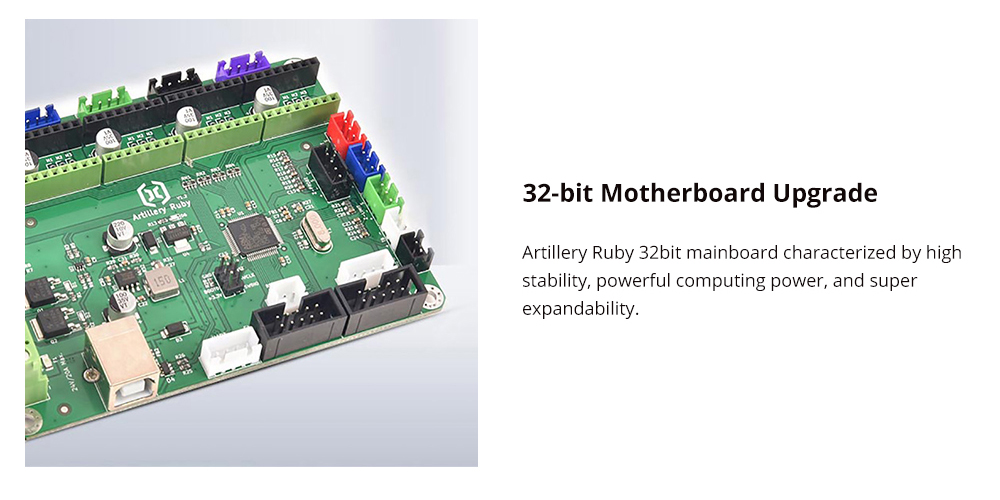

| Specification | Build volume: 300 x 300 x 400 mm Layer resolution: 0.1mm – 0.35mm Filament diameter: 1.75mm Supported materials: PLA, ABS, Flexible PLA, Wood, PVA, HIPS Frame: Aluminum Extrusion XYZ resolution: 0.05mm, 0.05mm, 0.1mm Nozzle diameter: 0.4mm Nozzle heat up time: < 3 minutes Build plate heat up time: 80C in less than 2 minutes Operating sound: < 70dBA Power consumption: 110V 700W max (w/ heated bed turned on) Control board: Ruby 32 Product dimensions: 21.65 x 15.94 x 34.25 in (with spool holder) Maximum Print Speed: 150 mm/s Maximum Travel Speed:250mm/s Maximum Build Plate Temperature: 130˚C Connectivity: USB, TF Card, USB Stick |

| Weight & Size | Product Weight: 12.9kg Package Weight: 16kg Product Size(L x W x H): 55*40.5*87cm Package Size(L x W x H): 66.8*50.8*31cm |

| Package Contents | 1 x Artillery Sidewinder X2 3D Printer 1 x Assembly Tool Kit 1 x Assembly Instruction 1 x Assembly Guide |

Videos

Customer Photos

Customer Videos

Customer Reviews

| 5 star | 284 | |

| 4 star | 6 | |

| 3 star | 6 | |

| 2 star | 0 | |

| 1 star | 0 |

- All (296)

- Images (50)

- Videos (0)

Questions & Answers

FAQ

Q1: What if my hotend/heated bed starts heating after powering on?

A: 1. Power off the printer immediately;

2. The problem was caused by a faulty mosfet on the mainboard, replace the mainboard.

Q2: What if my printed mold is not sticking to the bed?

1. Re-level the bed, and make sure to pre-heat both the hotend and bed to the print temperature;

2. The print bed sticks better with a temperature around 10C higher than the bed temperature suggested by the most manufacturer;

3. Do not turn off the bed during printing, due to the nature of the coating, it will release the print once it’s cooled down, turning off the bed mid-print will cause the bed to release the print;

4. You may wipe the print surface with IPA once it’s completely cooled down. Never clean it with any cleaning products.

Q3: My build plate/Y-axis/platform is not stopping when homing, what should I do?

A: 1. Do a visual check on the endstop sensor, make sure it’s not crushed by the screw;

2. With the power turned on, use a piece of metal to trigger the Y endstop sensor, if there’s no red LED lighting up, the endstop sensor is faulty, replace endstop sensor;

3. Move the platform to the very front of the print and home Y individually, using a piece of metal to trigger the Y endstop sensor right after pressing home;

a. If the build plate stops, the sensor is working correctly, check if there is anything beneath the bed obstructing its movement;

b. If the build plate does not stop, the sensor is faulty, replace Y endstop sensor;

4. If none of the above solves your problem, contact customer services for further assistance.

Q4: My auto-level sensor does not perform a self-test, how to deal with it?

1. Power off the printer, and wait till the screen is completely off;

2. Power on the printer;

3. If the auto level sensor does not perform a self-test (probing pin comes down and up twice) when powering on, please perform the following:

a. Gently pull the pin down by hand a repeat steps 1-2;

b. If the sensor still failed to perform a self-test, contact customer service for a solution.